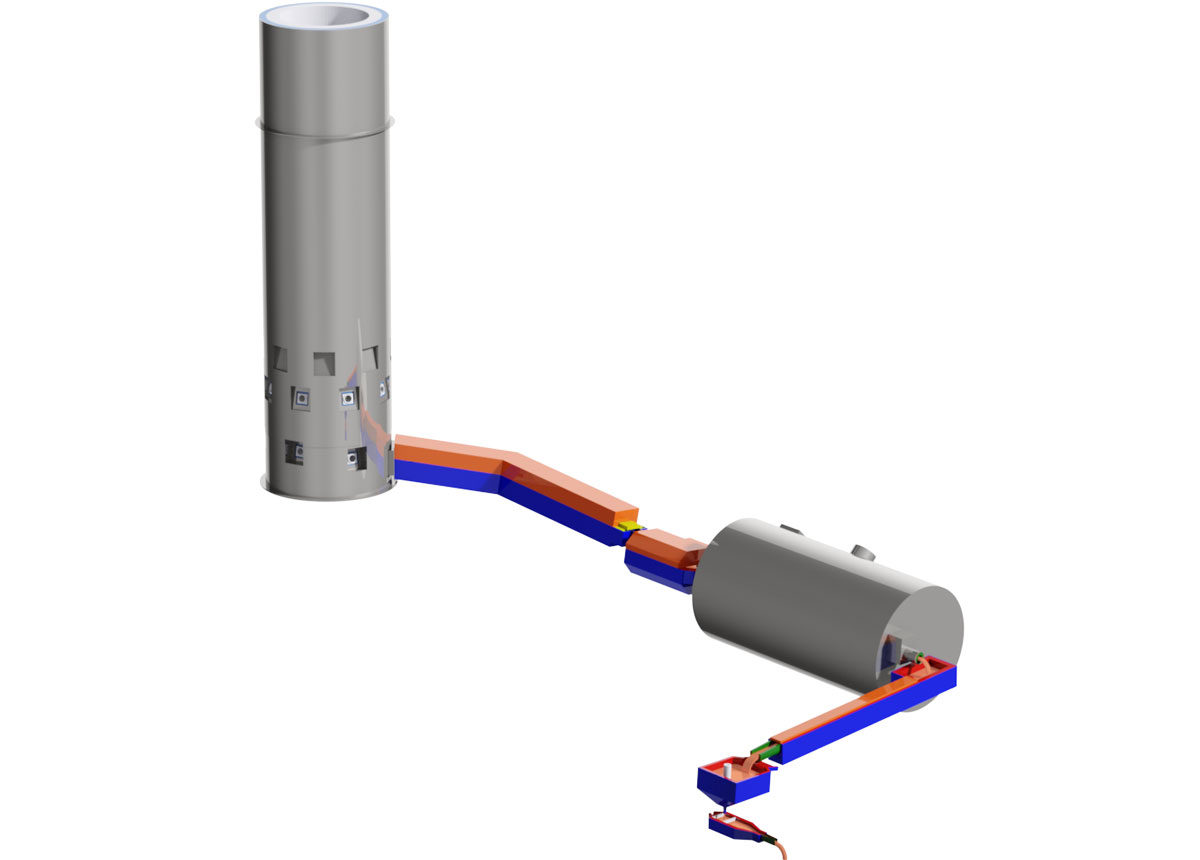

铜竖炉系统

| Area | Top Products |

| Copper Shaft Furnace | |

| Impact Zone | DURALAST SIC – Nitride Bonded SiC Brick METAL-ROK® ARMORMAX® 28 SiC |

| Lining | DURALAST SIC – Nitride Bonded SiC Brick MT-SC-85 SiC Mortar – Mortar for laying SiC brick. |

| Backup Lining | CAST 2800 – Castable backup for vertical section; behind impact brick. DRI-VIBE® 972CSF – Dry Vibratable Backup TUFFCRETE® 28 SIC Z – Backup castable for conical section; below metal line. |

| Subhearth Support / Subhearth | TUFF-FLO 50 – LC Castable for precast Subhearth Supports and precast Subhearth. |

| Burner Blocks | DURALAST SIC – Precast Nitride Bonded SiC Shape |

| Upper Launder |

|---|

| Working Lining | TUFFCRETE® 80 SIC – Field cast or Precast TUFFCRETE® 28 SIC Z – Field cast or Precast Field cast or Precast GT30CR – Field cast or Precast Field cast or Precast GT50CR – Field cast or Precast Field cast or Precast Nitride Bonded SiC Brick |

| Spout | TUFFCRETE® 60 SiC – Precast |

| Slag Trap |

|---|

| Working Lining | TUFFCRETE® 28 SIC Z – Cast ARMORMAX® 28 SIC – Cast GT30CR – Cast GT50CR – Cast DURALAST SIC – Nitride Bonded SiC Brick |

| Holding Furnace |

|---|

| Working Lining | DURALAST SIC – Nitride Bonded SiC Brick MT-SC-85 SiC Mortar – Mortar for laying SiC brick. |

| Exit Spout | TUFFCRETE® 60 SIC – Precast Cylinder LITE KASTITE 3000 – Insulating castable backup |

| Lower Launder |

|---|

| Working Lining | GT30CR – High chrome if oxygen is being injected LCF316CR – High chrome if oxygen is being injected TUFFCRETE® 80 SIC – Field cast or Precast shapes TUFFCRETE® 28 SIC Z – Field cast or Precast shapes DURALAST SIC – Nitride Bonded SiC Brick |

| Metering Box |

|---|

| Working Lining | TUFFCRETE® 28 SIC Z – Cast TUFFCRETE® 60 SIC – Cast ARMORMAX® 28 SIC – Cast DURALAST SIC – Nitride Bonded SiC Brick |

| Stopper Rods & Nozzles |

|---|

| Stopper Rods | Hagenburger Stopper Rods – Isostatically pressed graphitized Alumina |

| Nozzles | TUFFCRETE® 60 SiC |

| Tundish |

|---|

| Working Lining | DURALAST SIC – Nitride Bonded SiC Brick ARMORMAX® 28 SIC – Cast TUFFCRETE® 60 SIC – Cast |

关于联矿,了解更多

我们的成功在于定制化的耐火材料产品,积极应对问题,技术支持和全球保证。我们所做的一切都是为了使客户受益。关于联矿,了解更多。